Boot F A Q

Frequently asked Questions

Last updated August 2018

Click the question to go to the answer or scroll through this page...

all of the questions and answers are on this

one page.

Special treat at the bottom of the page.

-

Could you please send a catalog?

-

How can I find the prices for your boots?

-

What kind of socks should I wear with my boots?

-

Can you omit the stamped Wesco logo on my custom boots?

-

My husband is a lineman ........ Is there anything he can do to stop his boots

from molding and mildewing?

-

What kind of data do you gather on visitors to your web site?

-

Do you make customer information available to others?

-

What do you recommend for waterproofing boots? How about Snowseal?

-

You describe your Engineer's Boots as having a "hard toe". What makes it hard?

-

There is almost a whole size difference between my feet.

Should I order for

the larger foot or order a size halfway between? -

What is the difference between custom boots, made to measure boots

and stock boots?

-

What is the difference between Dehner Sr. and Dehner Jr. boots?

-

My boots have been soaked. What should I do?

-

I've heard that you shouldn't wear the same footwear every day. Why not?

-

Are the buckles on the Boss Engineer boots brass or nickel?

- Are the lacing hooks and eyelets on Wesco boots brass or nickel?

-

I can't figure out how to lace my Dehner Boots. Can you send me instructions?

-

What does the term Bal-laced mean?

-

How long should replacement laces be?

-

OK -- I need 120" laces but I can't find anyone who sells them.

-

Harder rubber on the Vibram #100R sole - less flexible?

-

If those #100R soles are so great why don't you use

them on all of the boots?

-

How do I get the ankle to crease nicely?

-

Care and feeding of Dehner boots

-

I was looking at the picture of the

Vibram soles on your website. I noticed they are stitched through the soles.

I can't believe the stitching would last since

the outer loops will eventually wear through.

Won't the stitching just unravel?

-

Why does it cost so much to get boots made with black

thread instead of the normal white & brown... surely colored thread can't be that expensive.

-

I'm confused about boot height. My Jobmaster 10" lace up boots

only come 9" up my leg when I have them on, but, when I measure the

height of the boots from the floor to the top I get 10½". But my 11" Boss

Engineer pull on boots came 11" up my legs when they were new.

Nothing makes sense. What's that height specification refer to?

-

I've got very narrow feet and have

always had problems with my heel pulling up, particularly in slip on shoes like

loafers. Will I have this problem if I order a pull-on Boss engineer boot in my

narrow size?

-

I just received my Wesco Boss boots, and they're

wonderful, but they're very tight across the top of my foot at the instep. I thought

they'd loosen up after I wore them a bit, but they're still tight and it hurts my feet. What can I do?

-

I'd like to blacken the white and brown stitching on my black Wesco

boots. How do I dye the stitching without damaging the leather. Also... how can I dye the black leather on Wesco

boots when it starts loosing its color?

-

Can you make my boots with Wesco's original last which

featured the more roomy "bump" toe?

-

Your boots are all shown in men's sizes... what about women's sizing?

-

When you describe insole and midsole construction in terms of "9 iron leather" or "8 iron rubber" just how thick is that?

-

Could you please send a catalog?

Ok... you're looking at it... you already have it. Our web site is our catalog. It provides more detailed information and more pictures than most print catalogs and is always more up to date. Not only that, you already have a copy in front of you. Just click away!

If you want a hard copy to send to someone else, then just print the pages on your printer.

-

How can I find the prices for your boots?

Each boot information page shows the price for various configurations of the boots and any options which are available. Just scroll down through the information on the page until you find the prices. Note that most of our pages are long and designed so you can scroll down through all of the basic information instead of mimicking a magazine where we show you one page at a time. -

What kind of socks should I wear with my boots?

Good socks provide a cushion between your feet and the boot and help your feet to breathe and stay dry. Good socks wick away moisture while maintaining that cushion. Heavy boots such as our Wesco boots are intended to be worn with heavy boot socks which provide padding between the feet and any pressure points in the boots. The heavier socks also improve ventilation and keep your feet and boots drier when compared to lighter socks.

Dressier boots, such as the Dehner Motor Patrol boots, are often worn with lighter boot socks because they are a lighter weight boot.

Before we tell you what kinds of socks are good for boots we need to tell you about bad socks.

Bad Socks

Cotton socks are Bad Socks. They don't work. Even when they're thick, comfortable and dry when you first put them on, cotton socks soon soak up moisture, become soggy and loose their ability to cushion your feet. Your feet and boots will become soggy and stay that way until you take your boots off and thrown the soggy, smelly cotton socks in the trash. Ever wonder why cotton boot socks advertise that they're treated with anti-microbial chemicals? It's because they'd rot even sooner without that treatment.

Cotton socks soak up moisture then hold on to it instead of wicking it away. Once they're wet they loose their cushion. Constantly wet feet, socks and boots lead to athelete's foot and smelly feet and boots. The bacteria and fungus which grows in the damp conditions damages your feet and reduces the life of your boots. You can't afford to wear cotton socks in your expensive boots.

- Cotton socks are bad for the health of your feet

- Cotton socks are bad for comfort once they get soggy

- Cotton socks are bad for your boots since they keep them soggy

- Cotton socks wear out much quicker than other socks... that's why stores sell them... constant repeat business

So never wear cotton socks with any footwear... they suck! When you see someone who runs to their pickup after work and can't wait to change out of their boots before driving home it's probably because they're wearing soggy cotton socks.

Folks who wear good socks and quality boots drive home with their boots on.

Good Socks

So what are "good socks"?

Good socks are made out of a springy, cushiony material which wicks moisture away from your feet but, unlike cotton, doesn't hold onto the moisture. For wear with work boots it's usually better to get thicker socks which provide more cushion and do a better job of keeping your feet dry.

Good socks are typically made from a mix of modern materials such as: Acrylic, Polyester, Polyropylene, Olefin, Nylon, Spandex, Coolmax. Boot socks often also contain wool because of it's excellent properties.

In cooler weather, socks provide insulation to keep your feet warm. In general, thicker socks made of synthetic blends (and, optionally, wool) keep feet warmer in cold weather and cooler in hot weather when compared to socks made of cotton or thin synthetic materials.

Socks for Cold Weather:

Thick socks made from synthetic blends (and, optionally, wool) keep your feet warm and dry in cold weather

Socks for Hot Humid Weather

Thick socks made from synthetic blends (and, optionally, wool) keep your feet cooler and dryer in hot humid conditions than thinner socks or cotton socks.Socks for All Conditions:

Thick socks made from synthetic blends (and, optionally, wool) are the best choice all year round.

For the dressier boots such as the Dehner patrol or equestrian boots, an athletic sock, heavier dress sock or light weight boot sock works well. Different weights of socks can always be used to adjust the fit.

For heavier boots, one of the best all-around combinations is a pair of heavy (but soft) wool socks worn with a thin polypropylene inner sock. The best wool socks are 85% wool, 13% nylon and 2% spandex. The polypropylene socks wick moisture away from the foot and solve the "itch" problem some people have with wool socks. The wool socks provide good cushion, carry away moisture and dry quickly after they've been soaked. The disadvantage is that wool socks are more expensive and they are more fussy about the way they are washed and dried.

So a good choice for all conditions is a heavier boot sock made of synthetics or a blend of synthetics and wool. A typical, widely available sock which meets these specifications is the Fox River "Wick Dry Outlander" sock which contains 65% acrylic, 20% wool, 14% stretch nylon, 1% spandex. Photo is to the right.

-

Can you omit the stamped Wesco logo on my custom boots?

Wesco will omit the logo only for uniform boots. For all other boots, Wesco stamps their logo

on the exterior of their boots.

Wesco will omit the logo only for uniform boots. For all other boots, Wesco stamps their logo

on the exterior of their boots.

On lace-up boots, the logo is placed on the exterior just below the top of the boots on the left side of the left boot and the right side of the right boot.

On pull-on boots, the logo is placed on the exterior just below the top at the front of each boot.

To quote Wesco: "The Wesco Logo will always go on the exterior of the boot with the exception of the following: Military, Regulation footwear (i.e. Law Enforcement) footwear that does not allow logos on the exterior."

-

My husband is a lineman and has a pair of the linemen's boots. He is constantly oiling them and

cleaning them to make sure they last just as long as the possibly can (due to the cost).

He wears them five or six and sometimes seven days a week. His feet and legs sweat profusely,

and this has caused the inside liners to begin molding and mildewing. Is there anything he can do

to stop the boots from molding and mildewing? This is the only pair of boots he has at the time,

so the maximum number of days he is out of the boots is two. I would really appreciate any help

you can give us. I asked a local shoe repairman (one of the old-time ones) but he was unable to help me.

(updated July 2012)

Once the boots start getting moldy, it is hard to do very much. The only sure solution is to have 2 or more pairs and rotate wearing them. That way, they will have a chance to dry out and mold / mildew can't grow. This might seem expensive at first but its much cheaper in the long run because each pair will last much longer.

Of course, between wearings, place the boots in a location with good air circulation or use a non-heated boot dryer to circulate air into the boots. If you keep them in a very cold location, they will be very slow to dry out and will easily mildew. Mud rooms are particularly bad for boots. Heated boot dryers can be used as long as they have a thermostat to keep the temperature at a safe level (under 100°F / 38°C). Unfortunately, most of the heated ones don't have a thermostat.

There are a few things which may help the existing boots. You can dust the inside of the boots with baking soda (sodium bicarbonate / NaHCO3) before washing them inside and out with saddle soap. That will help soak up moisture, neutralize acid and reduce odor. Pour in some baking soda, shake to spread it around then let the boots sit for a few hours or overnight. Use a couple of handfuls or more. When you're ready to wash the boots, pour out excess baking soda then lightly rinse the interior with water.

Thoroughly wash the boots INSIDE and out with saddle soap. Don't rinse the saddle soap off the boots. It is has a basic pH and helps neutralize acids and the glycerin in it keeps the leather healthier and more supple.

Finally, you can use good athlete's foot spray inside the boots to fight off mold. Use a liquid spray, not a powder. If you can find a generic spray with one of these active ingredients, it will be much cheaper and just as effective. Here are a few effective sprays:

Brand active ingredient Lotrimin Liquid Spray Miconazole Nitrate (2%) (Antifungal) Ting Liquid Spray Tolnaftate (1%) (Antifungal) Tinactin Liquid Spray Tolnaftate (1%) (Antifungal) Lamisil Liquid Spray Terbinafine Hydrochloride (1%) (Antifungal)

It's a good idea to wear thicker wool or synthetic socks. They will wick away moisture and keep feet cooler in warm weather and warmer in cool weather. (Really! No S_t!) Avoid cotton socks. They soak up sweat and retain the moisture without wicking it away.Finally... it's a good idea to pull the insole liner out of the boots after wearing them so that the boots and the liner can dry more easily. Never use the popular insole liners which are made of rubber or gel or plastic in ANY footwear. This type of insole liner traps moisture between it and the insole and encourages mildew, mold and rot. Even if you take those rubber liners out after wearing, they make your feet very sweaty and hot while you're wearing them because they inhibit air circulation between the bottom of your foot and the boot.

Try to find an insole liner which is made of fabric, felt or the new breathable plastic foam such as the Ortholite™. You can order replacements from Wesco if you have problems finding them locally.

-

What kind of data do you gather on visitors to your web site?

The only data we gather is the standard accounting data collected by our service provider. This consists of the network IP address of the computer system from which the page was requested and the time of the request. This information can be used to show approximately where the request to view a page came from. For instance, it would be possible to determine if the person who requested a page was on AOL or zonk.com, but no more specific information than that.In August 2001 we started using cookies to make our ordering system more automated and helpful. A cookie is a file left on your machine by a web site to record information about your visit to that site. They can expire in hours or days, but most web sites make them stay on your machine for a decade or more. The cookies we use only contain information about the boots you order and their options. We do not put any other information in cookies and we don't use cookies if you aren't ordering boots. Unlike most web sites, we don't leave a mess behind. Our cookies expire within a day.

We do not examine cookies left on your machine by big marketing firms such as Microsoft.

We are not able to determine your userid or email address. That is why our order forms ask you to fill in your email address.

Our goal is to make our web pages readable by ALL browsers, not to annoy you by presenting some gimmick which is only supported by one browser or another.

-

Do you make customer information available to others?

NoBIG BLACK BOOTS does not provide customer information to anyone not directly involved in building your boots or shipping your order.

-

I have been using SnowSeal on my boots and wonder if you recommend something different? (updated July 2012)

The following advice is especially applicable to the oil tanned leather with a natural finish which is used to make Wesco boots. If your boots have a shiny surface and are polished with shoe wax, the surface is sealed so the leather won't take up much oil or grease.

SnowSeal is good for the sole edges and seams, but may be a bit of an overkill on the rest of the boots. We like the beeswax based boot grease or bee oil for both the standard oil tanned leather and the silicon tanned leather. These are a mix of beeswax and oil. SnowSeal is thicker and stickier and does not breathe, but it's great for sealing the seams and the interface between the soles and the boot uppers.The goal is to keep the water out but let the boots breathe, so the larger leather surfaces should be greased or oiled. The oil and grease soak deep into the leather. Leather treated this way will repel water but still let air slowly pass through the leather to keep it dry. Of course, this means that you should touch up your boots with more grease or oil when the leather dries out. Continued exposure to water slowly rinses the oil and grease out of the leather. Likewise, dry hot weather will tend to carry some of the grease and oil out of the leather. Dust and mud gets on your boots and wicks out the oil like sand on an oil spill.

You could use shoe polish on your boots, but the wax tends to stay on the surface, doesn't soak in much and keeps the leather from breathing.

Many products sold for boot care contain harsh petrochemicals and are expensive to use since they don't go very far in taking care of a pair of heavy duty work boots.

So we prefer products like the Wesco Bee Oil and the Wesco Bee Oil Plus which is a heavier boot grease. You can order these using the accessory order form which comes with your boots. We also like the Obenaufs boot grease and boot oil which are similar to the Wesco products but available in larger, more economical sizes (how about a gallon!).

Visit the Obenaufs web site to read about the excellent properties of their boot grease and boot oil... they call these products "LP - Leather Preservative". These not only have oils and beeswax, like the Wesco Bee Oil, but also contain bee propolis which acts as a preservative. Propolis is derived from tree resins with anti-bacterial properties and is gathered by honey bees to waterproof & preserve their hives. Propolis resists bacteria and mildew, and is a barrier against manure acid, salt, caustic chemicals, and petroleum. Combined with beeswax it repels water better and longer.

Huberd's Shoe Grease is another excellent beeswax based grease for your boots. It uses highly purified turpentine (made from pine tree resin) to carry the beeswax deep into the pores of the leather. The turpentine then evaporates and leaves the beeswax in the leather. Huberd's also sell an excellent beeswax and oil mixture which is similar to Wesco bee oil and Obenauf's oil.

If you don't have any leather care products handy you can always use hand lotion if it contains more oils than glycerin. (check the label). Dry skin and leather are the same thing and need the same kind of care. If it's good for your hands, it's good for leather boots. We often oil our boots using a good hand cream such as Lubriderm. At discount stores such as Costco this would be available at about $0.25 per ounce. You should preferably use a hand lotion which has more oil than glycerin... just look at the ingredient list. You can find unscented hand lotion if you shop a bit.

So hand lotion with oil and glycerin works well when you don't have access to purpose-made leather care products.

You can find leather care products made from beeswax and oil anywhere in the world. This formula has been used for thousands of years to care for leather and is still used to care for saddles and harnesses. So it will be available in equestrian stores and many stores which sell farming supplies.

-

On your web site you describe your Engineer's Boots as having a "hard toe". Just

exactly what is it that makes it hard? Is it some sort of insert (such as

fiberglass), or is it just an extra thick, stiff leather?

Here is a cutaway picture of the Wesco boot toe. The picture shoes the construction of the hard toe which is the inner leather layer and outer leather layer with a fiber insert between them to give the toe its shape. The fiber insert is soaked in glue to make it stiffer and to help hold the toe area together. Of course the heavy 7 oz. outer leather and the 4 oz. lining leather are very sturdy in their own right!

Wesco boots can also be ordered with a steel or composite safety toe which provides additional protection. The steel and composite toes both meet the performance requirements for ANSI-Z4 PT83 impact and compression class ratings. -

There is almost a whole size difference between my feet.

Should I order for the larger foot or order a size halfway between my

two feet.

In general when there's a size difference, you should get boots the size of your largest foot. One foot will fit perfectly, the other will be slightly roomier and you can adjust the fit by adding an insole liner on that foot.

If you split the difference, the largest foot would be cramped into a boot that's too small.

In your case, since you have that much difference in size, you should either order two different size custom boots or have them custom made to measure. We can have any pair of Wesco boots custom made so that each foot is a different size... just put a note in the remarks section of the order form.

-

I've read about custom boots, made to measure boots, custom fitted boots and stock boots.

What is the difference between them?

(updated July 2012)

Depending on the style and manufacturer of the boots, they fall into one or more of these categories:- Stock or "Ready to Wear" boots

- Custom made boots

- Made to measure boots

Some of our boot styles fall into all three categories:

- Stock or "Ready to Wear" boots

- These are boots which are already made and sitting on the shelf.

They can usually be shipped to you as soon as we receive your order unless we're

temporarily out of your size.

If we don't have your size, we often have these shipped directly from the

factory to speed things up. If the factory is also out of your size, there are

usually more available soon since these are in production constantly.

Here are the boots which are normally in stock:

- Dehner "Ready to Wear" Motor Patrol Boots

- Dehner "Ready to Wear" Equestrian Boots

- Wesco Highliner Lineman's boots in a wide range of sizes & heights

- Wesco Firestormer Wildland Fire boots in a wide range of sizes

- Wesco Jobmaster work boots in many sizes & heights and colors

- Wesco Boss Engineer boots in black 16" 2 top buckle configuration

- Cosmas Hercules V2 Wildland Fire boots in a wide range of sizes

- Grinders Ranger boots in 14-hole and 20-hole heights

- Custom Made boots

- These are boots custom made to your specifications in standard sizes.

Since so many of our boots are available in a variety of heights, leather types, colors and soles

types, they are custom made to your specifications. Most of our Wesco boots are

custom made to order.

Wesco's production time for a pair of custom boots varies through the year depending on

demand.

In years with busy fire seasons, production time can be very long during the summer and early fall

because of the demand for the wildland fire boots.

Currently it's taking about

14 weeks

for lace-up

boots and

14 weeks

for pull-on boots.

Custom Made boots cost about $10 more than equivalent stock boots.

- Made to measure boots

- These are custom boots made to your exact measurements

and specifications instead of just to a particular size. Wesco boots under 20" tall cost $99 extra when made

to measure. Once your measurements are on file, subsequent orders cost the same as any custom

boot... the charge is for the bootmaker to make a pattern for your foot and leg.

Except for the stock motor patrol boot and the stock equestrian boot, all Dehner boot styles are normally made to measure and there is no extra charge for the service.

- We handle Dehner made to measure boots -- the required measure form can be downloaded from our order forms

- For made to measure orders we handle only the "Big Boss" over the knee styles. When you order these boots we will send you a measure form. For other types of Wesco boots we refer you to Wesco directly. (800) 326-2711. Note that we will handle Wesco made to measure orders if your measurements are already on file from a previous order. There is no extra charge for these follow-on orders.

- What is the difference between Dehner Sr. and Dehner Jr. boots?

Lots of motorcycle patrol officers refer to the stock / ready to wear Dehner motor patrol boots as the Dehner Jr. and the made to measure motor patrol boots as the Dehner Sr. We charge $429 for the stock / ready to wear Dehner motor patrol boots and around $685 to $1,010+ for most of the made to measure boots. That may explain the terminology :=)

- My boots have been soaked. What should I do?

(updated July 2012)

Boots are made to be worn in wet conditions, so this is not a problem. Think of all the loggers and forest workers who wear Wesco boots in wet forests. The Dehner equestrian and Motor Patrol boots get wet all the time.

The first thing to consider is that boots should be oiled, greased or waxed regularly to be more resistant to water.

Once they're wet, however, they should be dried as soon as possible with room temperature, dry air. If you let your boots sit while they're wet and don't dry them, they will grow mold and mildew.

Place your boots in a location with good air circulation or use a non-heated boot dryer to circulate air into the boots. If you keep them in a very cold location, they'll be very slow to dry out. Mud rooms kill boots. Heated boot dryers can be used as long as they have a thermostat to keep the temperature at a safe level. Temperature should be kept under 100°F / 38°C, preferably not higher than 80°F / 27°C. Most of the heated dryers don't have a thermostat, so they can damage your boots. Don't be tempted by these. The safest option is to get a dryer which has an option to gently circulate air without heating it. This dries the leather more gently. Your boots will usually dry overnight as long as the ambient air is at a comfortable temperature. Just a small airflow is all that's needed... a strong blast of air isn't useful.

It's important to avoid overheating boots because this will literally cook the leather and cause it to become stiff and brittle. The best technique is to ensure that dry air can circulate inside the boots. Good ventilation will dry them safely and quickly.

On the other hand, if you let the boots sit in a wet condition for days without drying out, they can become moldy. This isn't good for the boot and mold / mildew stinks and is nearly impossible to get rid of.

So what is "room temperature" air? Something between 70 to 95 degrees Fahrenheit or 20 to 35 degrees Celsius.

If you're in a situation where you can't properly dry your boots, then keep them on and wear them in a dry area until they can dry out before you take them off. They'll actually do better if you wear them a while in a dry area before taking them off. Your body heat and the dry air do a good job getting rid of most of the moisture.

- I've heard that you shouldn't wear the same footwear every day. Why not?

Because your feet will stink and your boots will rot.

Next question please...

How inelegantly put!... but true. If shoes or boots are worn every day without being able to get a rest and, essentially, dry out, they start growing bacteria, fungus and all sorts of things. High quality tanning of the leathers used in our boots discourage this, but can't completely prevent it. The bacteria, fungus, etc. eventually cause foot odor and cause the leather to deteriorate.

How to prevent this? If you alternate your footwear, and give your boots and shoes a rest between wearings, you will discourage the growth of bacteria, fungus etc. They last longer and stay in better, "sweeter" condition. Your feet are healthier too.

If you have two pairs of boots and alternate wearing them, they will last more than twice as long as a pair worn every day.

In conclusion... it is more expensive in the short run to buy several pairs of boots, but you will be rewarded in the long run because they will all stay in good condition longer.

- Are the buckles on the Boss Engineer boots brass or nickel?

On both Wesco and Dehner boots, the rule is silver colored nickel hardware on black leather and gold colored brass hardware on brown leather.

By hardware, we mean the buckles and harness rings.

It is possible to substitute nickel for brass and vice versa on any custom order. Just put a note in the remarks on your order.

- Are the lacing hooks and eyelets brass or nickel?

Yes.

The eyelets and lacing studs used on the Highliner lineman boots and the Jobmaster logger boots are thick, solid brass which has a gold color. Brass eyelets and studs are used on all leather colors.

For custom or made-to-measure orders, we can substitute nickel eyelets and studs which have a polished silver color. This is an extra cost option. Just put a note in the remarks on your order.

We can also put black studs and eyelets on Wesco boots... this is also an extra cost option.

-

I can't figure out how to lace my Dehner Bal-laced Motor Patrol Boots. Can you send me instructions?

We've had this question on more than one occasion, so we designed a diagram showing how to do it. You'll find this diagram also at the Dehner web site.

- What does the term Bal-laced mean?

Click here for an explanation of the term, a picture of the Dehner Bal-laced instep and a diagram showing how to lace the boots..

- I need to replace the laces on my boots... how long should the new

laces be?

Here's a chart showing manufacturers' recommended lace length for various types and heights of boots - this is the length originally installed on new boots. Some of these are longer than needed for most people but you can either wrap the extra around the top of the boots or you can cut the laces shorter - the following article in this FAQ discusses how to do this:

Dehner Bal-laced Instep

waxed cotton36" 91 Cm Dehner Bal-laced Instep

stretch laces34" 86 Cm Dehner Mountie Boot Instep 45" 115 Cm Wesco 6" Boots 54"

137 cm

Wesco 8" Boots 63" 160 Cm Wesco 10" Boots (regular toe) 72" 183 Cm Wesco 10" Boots (lace-to-toe) 84" 214 Cm Wesco 12" Boots (regular toe) 84" 214 Cm Wesco 12" Boots (lace-to-toe) 96 244 Cm Wesco 14" Boots 120" 305 Cm Wesco 16" Boots 120" 305 Cm Wesco 18" Boots 120" 305 Cm Wesco 20" Boots 134" 340 Cm Wesco 35" Boots 285" 724 Cm Grinders 14-hole Boots

come with 100" but 90" is fine90" 230 Cm Grinders 20-hole Boots 130" 330 Cm 30-hole Boots 150" 381 Cm Cosmas Hercules V2 Wildland Fire Boots 84" 214 Cm

- OK -- I need 120" laces but I can't find anyone who sells them.

> You can order replacement laces directly from Wesco or Dehner.For our Wesco and Grinder boots, you can also use nylon parachute riser cord which is easily available from sporting goods stores and surplus dealers. You can get 100' / 50 meters and spend very little. Cut to desired length then melt the ends so they don't fray. This cord is used in parachutes and often used to lace combat boots and jump boots. It's thicker and softer than the typical work boot laces such as those used by Wesco and easier on the hand when lacing boots.

The cord to use is MIL-C-5040H Type III paracord. It has a braided outer covering containing 7 strands of nylon cord. The real stuff is fat, 450 or 550 Lb. test and is round. Cheap imitations typically have the braided outer covering but inside are 5 strands of cheap, non-nylon, mono-filament line. The cheap imitations don't hold their round shape and get much thinner when stretched.

This cord is commonly available in white, black, olive drab, "desert tan" and "foliage green". It's also available in about 30 additional colors though harder to find.

Be careful not to touch the nylon when it's hot and soft. You can get a serious burn because the heat-softened nylon will stick to your skin.

-

Does the harder rubber on the fire resistant Vibram #100R sole make it less flexible/pliable? Would it be noticeable?

The #100R Vibram lug sole seems to be just as flexible and pliable as the standard #100 sole, it just doesn't leave marks. If I had to describe the difference another way, the standard #100 sole feels a bit like a pencil eraser when you rub it. Bits of rubber dust will come off.

When you rub the #100R sole, no rubber dust comes off. It feels more plastic like but very flexible and bouncy... sort of like a heavier version of a Dr. Marten air sole.

If you're aware of the difference between natural rubber and neoprene rubber, the #100R soles feel closer to neoprene than to natural rubber. I haven't burnt any of these yet to see just how much more fire resistant they are, but I wear the #100R soles on one pair of Highliners and they don't leave scuff marks on the floor... other than that, I haven't been able to notice the difference while wearing them. I found it to be worth the extra cost not having to clean up the scuff marks on my floors.

The special #100F fire resistant soles are also oil-resistant and seem to fall between the standard #100 Vibram soles and #100R Vibram soles in terms of hardness, pliability and floor marking.

-

OK -- if those #100R soles are so great why don't you use them on all of the boots?

These soles are so special they aren't even listed in the Vibram catalog for shoe manufacturers. They're made from a special, non-standard, more expensive rubber compound which costs considerably more than the standard soles. So the special #100R soles are used as an extra-cost option on boots.

The standard #100 Vibram soles are still one of the best soles made for boots and actually perform better in fire situations when properly installed on the boots as Wesco does. The #100R are better at resisting damage from heat and more tolerant of oil than the #100 Vibram soles. I guess this makes them a good choice to wear to a siege where hot oil may be poured from the battlements.

The feedback we get from wildland fire crews is that the #100R soles resists hot temperatures better, but, when they finally are heated too high, they get gooey. The #100 soles are not quite as heat resistant, but, when they are heated too high, they char, but don't get gooey. Wesco switched back from the #100R soles to the #100 soles on the Firestormer boots after getting this feedback. Then, when Vibram developed a "new and improved" fire-resistant sole material, Wesco switched to the Vibram #100F soles which use this new material.

So the Vibram #100R is an excellent sole which has very good properties, but the #100F sole is now the preferred sole to wear to a forest fire.

Both the #100R and #100F Vibram lug soles are special purpose soles which are not shown in the normal Vibram catalog.

- How do I get the ankle to crease nicely?

When you get a new pair of pull-on boots, such as the Dehner Motor Patrol boots, Wesco Boss Engineer boots or Harness boots you can train the ankles to crease nicely. It's best to do this when your boots are new and before you've worn them too much.

The goal is to make the crease at the ankle break straight across the front and back rather than at an angle. The boots will look better and may be more comfortable. When this is done correctly, the sides of the boots near your ankle bone will have a classic "dimple". The picture of the Wesco Boss boot on the right shows how this looks. The Dehner boots will also have a dimple, but it won't be as prominent because the ankle lining is more supple.

Wesco boots with the leather lining will end up with the correct front and back crease, but the dimple won't develop because the leather is so thick. This "dimple" which looks like a leather dice cup is what gave the German infantry boots the name "Knobelbecher" (dice cup) because they would develop that characteristic dimple when broken in.

How to discipline your boots...

You can do this while sitting on the couch watching the news... takes about 5 to 10 minutes. Best done when the boots are new and before they develop bad habits such as creasing inelegantly.

Put your hand down into the boot and slowly flex the shaft forward and backwards. Use your fingers on the inside to pinch the crease in the front and back of the ankles. Train that fold so that it goes more or less horizontally across the front and back of the ankles. Left to their own devices boots sometimes develop a crease which is a bit crooked.

The technique is to slowly start flexing... note where the boot wants to crease... if it isn't creasing straight across... then reduce the flex... pinch the boots on the inside as you flex to force the shaft to crease in the correct spot.

Once you have the creases working in the correct spot then spend some time flexing the shafts forward and backwards by hand to set the crease in place.

When you've done it correctly there will be a characteristic "dimple" on each ankle and gentle horizontal creases at the front and back of the upper ankle area.

- Care and feeding of Dehner boots.

(updated August 2015)

If you have stock ("ready to wear") Dehner boots with the older Dehcord shafts, Dehner used to recommend shining the shafts with a spray furniture wax such as Pledge instead of using shoe polish. This made maintenance fast and easy and prevented polish build-up on the shafts.

In 2012 Dehner started using a new material called Majilite on their stock motor patrol boots. We like this new material. It's an excellent match for the leathers it's mated with, it is breathable and is expected to have a longer service life. However several customers mentioned that the Pledge furniture polish doesn't work as well with the Majilite.

We did comparative test on both the older Dehcord and the new Majilite with several polishes and verified that the Pledge doesn't work as well on the new Majilite but found another product which works even better than the Pledge furniture polish used to. Best of all, this product works equally well on the old Dehcord material and the new Majilite material. It's also a great finish and maintenance shine for all leather boots polished with standard shoe polish.

That product is the "Express Shine" made by Kiwi. It comes in Clear/Neutral, which we tested, and black and brown. The black and brown versions add only a thin amount of black or brown color to the boot surface. We liked the clear version.

The product is a sponge in a plastic protective case.

There is a clear liquid, which may be a silicone wax, which slowly

soaks into the sponge. Kiwi's instructions are simple:

Remove heavy dirt from surface. Glide sponge lightly over leather.

We found that you can buff the surface with a soft cloth

a few minutes after applying the

Express Shine and achieve an even better shine.

The product is a sponge in a plastic protective case.

There is a clear liquid, which may be a silicone wax, which slowly

soaks into the sponge. Kiwi's instructions are simple:

Remove heavy dirt from surface. Glide sponge lightly over leather.

We found that you can buff the surface with a soft cloth

a few minutes after applying the

Express Shine and achieve an even better shine.

This product is available in most countries and there are similar products competing with it. One is a small disposable cloth with similar polish in a sealed packet.

Standard shoe/boot polish shouldn't be used on the Dehcord or Majilite shafts because it will eventually build up a thick layer of shoe polish which will flake and crack. However, you SHOULD use a good shoe polish on all leather parts of Dehner boots. The exceptions are the Dragoon leathers which are oil tanned and should be oiled instead of polished. The rest of Dehner's leathers need periodic applications of a good shoe/boot polish to keep the leather supple and shiny. The "cream" polishes are better for the leather because they soak in and keep it supple. However the harder polishes like Kiwi Parade Gloss achieve a shine which is more glossy. You may want to alternate between the two. What's different about the Parade Gloss? "It contains more carnauba wax than the regular polishes."

An easy way to get a nice shine is to polish the leather with standard polish then finish with a light all-over coat of Kiwi Express Shine. This protects both the leather and the Dehcord shafts and leaves a nice gloss.

Instead of trying to polish the soles and heel edges, use edge dressing. It's fast, seals the edges of the soles, hides nicks and scratches and looks better. Unlike leather dye, which is spirit based and designed to soak in, edge dressing is formulated to stay on the surface so it can seal and protect the sole and heel edges. Most edge dressing products are made of water based Acrylic paint.

From time to time you should wash the boot exterior with saddle soap. Our favorite is glycerine saddle soap which is pure soap and very kind to leather and to your skin. It has a translucent brown color and is made and sold all over the world. In the US, Fiebings and Lincoln both make excellent glycerine saddle soap which is available at riding shops and on the internet. It's good for leather and good for your skin.

If you have trouble finding glycerin saddle soap you can find un-scented glycerin soap anywhere in the world where skin care products are sold. This is the same type of soap. Glycerin saddle soap and skin care soap is valued because it is mild, contains no other additives or scents and is hypo-allergenic. This type of soap is always translucent and light brown.

There are other kinds of saddle soap. Most widely available saddle soap also contains wax and is an opaque yellow color.

The mixture of saddle soap and wax just doesn't work well for cleaning.

Kiwi's saddle soap is one of these and, unbelievably, is now lemon scented!

Great news for all who prefer lemon scented boots and saddles.

Dehner recommends against using the opaque yellow saddle soaps which

contain both soap and wax. The product can't decide what it's supposed

to be doing. Should it wax the dirt into the leather or wash it away?

The mixture of saddle soap and wax just doesn't work well for cleaning.

Kiwi's saddle soap is one of these and, unbelievably, is now lemon scented!

Great news for all who prefer lemon scented boots and saddles.

Dehner recommends against using the opaque yellow saddle soaps which

contain both soap and wax. The product can't decide what it's supposed

to be doing. Should it wax the dirt into the leather or wash it away?

Once you've cleaned your boots with glycerin saddle soap, just wipe excess soap and water off the boots with a clean cloth then walk away from your boots! You should not rinse the boots! Saddle soap cleans the leather, as you'd expect, but it also helps neutralize acids which can damage leather. The residual saddle soap acts as a buffer to neutralize acids in the future. When saddle soap soaks into the leather, the glycerine helps lubricate the leather and keep it supple along with oil and grease. Glycerin is one of main substances used to finish the tanning process when making leather. When your boots get soaked, some of the glycerin is washed out. Cleanning occasionally with glycerin saddle soap replenishes the glycerin.

You should also use saddle soap on the interior of the boots occasionally for the same reason you use it on the exterior. It neutralizes acid from perspiration, keeps your boots fresh and is good for lining leather. The entire interior of each Dehner boot is lined in leather. When you do the interior, use just enough water in the rag or sponge to do the job but avoid soaking the shaft interior. When the shaft interior is soaked, it can loose its shape. When done, don't rinse, but dry the interior thoroughly.

-

I was looking at the picture of the Wesco highliner boots with the Vibram soles on your website. I noticed they are stitched through the soles. I can't believe the stitching would last a week walking on any cement at all since the outer loops will eventually wear through. Won't the stitching just unravel?

You have a good question. It looks like the stitching would come apart and the soles would fall off once the soles wear down a bit since the outer loops for each stitch would be worn through.

This would certainly be the case if this was cloth, but with the leather and rubber soles the stitches stay in and do not pull out when the outer stitching loops wear through.

There are several reasons why the thread doesn't pull out and unravel as the soles wear down.

This is one of the secrets of boot making. The white "thread" you see is a very special cord composed of several ingredients... typically linen, cotton, dacron, nylon, kevlar and a special lubricant which makes the thread slippery enough for the special sole sewing machine to get through the multiple layers of leather and rubber. The lubricant is designed to quickly loose its slipperyness and becomes like a glue... holding the thread tightly in place. The moisture in the lube also causes the cord to swell up which further anchors it into the sole.

The special machine used to sew the soles is about 8 feet high and uses very thick sewing needles. This machine sews the sole on using a lock stitch which further prevents the stitching from unravelling.

Bootmakers used to be called "cordwainers" ("cordonniers" in French). One of the most closely guarded secrets of their trade was the special thread they made which held the soles on. The thread didn't deteriorate when wet or come apart as the loops were worn through. Linen and hemp were used in most of the formulas since they don't rot easily. Because of all the drug hysteria, hemp, unfortunately, is no longer used.

Of course this whole process is assisted by the extra strong glue which is used to hold the soles together. Most bootmakers these days just use the glue... Wesco uses glue then sews the soles on as well. It doesn't get any stronger. These are the boots worn by wildland fire fighters.

You may wonder why Wesco and Dehner don't use screws to help hold the outsoles on. (there are nails in the heels but not in the soles). The reason is to minimize the penetrations of the sole through which moisture could enter and rot the leather.

- Why does it cost so much to get boots made with black

thread instead of the normal white & brown... surely colored thread can't be that expensive.

Yeah... it's that special black dye... very rare... not much of a demand for that color.

Actually it's because the bootmakers have to change the thread in the sewing machines at each step which is more of a hassle than you'd think. You have to change the thread, re-thread the needle and change the thread in the bobbin then thread everything back through the guides on the sewing machine. Then, after sewing the bits and pieces in black, you have to do this all over again to change back to the white or brown thread. This has to be done at many points in the manufacturing process. This slows things down and makes the bootmakers grumpy, so the extra charge goes into a special fund to pay for their beer and reduce grumpiness.

Of course... you can simply use genuine black leather dye and apply with a small brush or cotton swab to the stitching. Let dry... wipe with an oily rag and you now have boots with black stitching. See our FAQ article on genuine leather dye before doing this.

- I'm confused about boot height. My Jobmaster 10" lace up boots

only come 9" up my leg when I have them on, but, when I measure the

height of the boots from the floor to the top I get 10½". But my 11" Boss

Engineer pull on boots came 11" up my legs when they were new.

Nothing makes sense. What's that height specification refer to?

You're right... none of this makes sense. But we can explain the nonsense.

The official height specification for a pair of boots refers to how high the boots are on your leg when being worn. So the height is measured inside the boots from the sole up to the boot top... usually along the back of the boots. The measurement on the outside of the boots from floor to boot top is not what we refer to when we say "boot height".

For pull-on boots things make sense. A 16" pull up boot should come 16" up your legs when new. As they break in they'll sag some as the ankles crease.

Lace-up boots, on the other hand, don't make much sense. All US made lace-up boots sold are about an inch shorter than the stated height. That includes the standard 10" combat boot.

Here's how this all came about. When you look at the standard regular-toe logger boots there are 10 sets of eyelets in what is called a 10" boot... then 12 set of eyelets in a 12" boot ... etc.. The lace-to-toe styles have 2 extra rows of eyelets - the semi-lace-to-toe styles have 1 extra row of eyelets.

Since the eyelets on US made boots are 1 inch apart.... people used to estimate the height of lace-up boots by the number of eyelets... but, because of the curve in the row of eyelets as they bend down the instep towards the toe, the boots are actually about 1" shorter than the number of eyelets. So a pair of boots which is described as 10" high is usually about 9" high and this goes for all heights. A pair of 20" laceup boots will come 19" up your legs. This 1 inch discrepancy applies to all lace-up boots made in the US including government issue combat boots.

Things get more complicated. British boots are described by the number of pairs of eyelets (or "holes") they have. Just to keep you on your toes, the distance between eyelets on British made boots is typically less than an inch and varies from one manufacturer to another.

You'll see that our Grinders boots are sold in 14-hole and 20-hole heights. The 14-hole Grinders boots are actually about 11" (29 cm) high and the 20-hole Grinders boots are about 15½" (40 cm) high. The distance between eyelets on the Grinders is about 2cm (¾")

Dr. Marten boots have various eyelet spacings... usually around 2cm but occasionally some pairs are at 1.5cm.

Finally... lace up boots typically have an even number of eyelets. So they only come in even heights. This is probably because some lacing methods only work with an even number of eyelets. Bal-laced boots such as our Dehner bal-laced motor patrol boots have an odd number of eyelets so the lacing, which ties in the middle set of eyelets, will look symmetrical when tied.

You had to ask :-)

- I've got very narrow feet and have

always had problems with my heel pulling up, particularly in slip on shoes like

loafers. Will I have this problem if I order a pull-on Boss engineer boot in my

narrow size?

Narrow feet can be a problem... usually because it's hard to find footwear, particularly boots, in narrow sizes. Fortunately we can solve that part of the problem because we offer Wesco and Dehner boots in very narrow sizes. When you do get your boots, shoes or sneakers in a narrow size they definitely fit better and are less likely to give you a problem with the heel pulling up. But pull on footwear of any kind, including a properly fitted Wesco Boss engineer boot, is still prone to heel pull up with narrow feet, particular when the boots are new and more stiff.

So, if it's an option for you, the lace up boots are a much better choice when you have narrow feet since the lacing system lets you adjust the fit so it's just right and the snug lacing holds your feet in place in the boots.

The difficulty with pull-on boots is that the instep has to be tight enough to hold your feet in place but loose enough so you can get your feet into the boots. The narrower the feet, the more difficult it is to get this balance right. It's a geometry problem. Narrow feet tend to be the about the same width from toe to heel so it's easy for the foot to slide forward and backward. Wider feet are wider in the toe area so they tend to grab the forefoot part of the boot and reduce the tendency for fore and aft movement.

The problem doesn't occur with lace-up boots since the lacing system tightens the instep area to keep any type of foot snugly in place.

If you experience this problem when the boots are new you can usually solve it by wearing slightly thicker socks and/or using thicker insole liners. On the other hand... if the instep is uncomfortably tight it can be stretched and we can show you how.

The Wesco and Dehner pull-on boots are built with insteps on the tight side when new to help keep them on your feet without having the heel pull up. As the boots conform more to your feet and the soles become less stiff the problem with heel pull is less noticeable.

It's worth noting that the bal-laced style of Dehner boot was designed to solve this type of heel pull-up problem. It is a pull-on boot with lacing in the instep to help adjust the fit of the instep.

- I just received my Wesco Boss boots, and they're

wonderful, but they're very tight across the top of my foot at the instep. I thought

they'd loosen up after I wore them a bit, but they're still tight and it hurts my feet. What can I do?

The advice below is for our Wesco pull-on boots but also applies to Dehner boots. The instep on both brands of boots will "stretch to fit" as you wear your boots but the Wesco boots are made of much thicker leather and are more likely to need a little help to get the instep stretched so it is comfortable.

The instep on pull on boots sometimes will feel tight. It is a fine art making the instep snug enough to hold your foot in place in the boots but loose enough so that you can get your feet into the boots.

And, since the instep area will stretch as the boots break in, the boots are deliberately made slightly tight so they won't be too loose after they break in.

So, if they are too tight when new, this is an easy thing to remedy because the Wesco boots are sturdy and are made of thick, supple leather. The leather will mold to your feet and stretch to fit as the boots break in... but you can speed up the process.

First thing is to remove the insoles while you break in the boots. This will give more room at the instep immediately. You can also wear thinner socks initially.

If this doesn't help enough, the next step is to actively stretch the leather which goes across the instep.

Loosen the instep straps then wet down the outside of the instep area with warm (not hot) water. Easiest thing is to soak a towel in warm water then wrap it around the instep area for a few minutes.

Then remove the wet towel and stuff a dry towel into the boot and pack it very tightly in the instep area.

Let the boots sit that way for an hour or two, then walk in them.

You may have to repeat this process several times. The leather in the instep area consists of the 7 ounce outer leather and the 4 ounce lining leather. Both are supple (and thick) and have lots of give.

Finally, if you still have a good boot repair shop in your neighborhood, this is something which you can have them do instead. There is actually a tool which is used to stretch tight boot insteps. But we prefer the previous method since it allows you to stretch in small increments and avoids over adjusting the fit.

The process just described works for most people who experience a tight instep when the boots are new. In particular, the only people who need more of a stretch are people who have unusually high insteps.

If you do have a very high instep and have always had problems with footwear being tight across the top of your foot at the instep then we recommend that you have your boots custom made to measure. This will ensure that the insteps are made with more room than normal and in proportion to your own measurements. Both the Wesco and Dehner boots can be custom made to measure.

- I'd like to blacken the white and brown stitching on my black Wesco

boots. How do I dye the stitching without damaging the leather. Also... how can I dye the black leather on Wesco

boots when it starts loosing its color?

The genuine black leather dye used by bootmakers is what you need. It's made with an excellent alcohol-based solvent which is very thin and penetrates thick oil-tanned leather without coating the outer layer of leather like paint. Because this dye penetrates so well, you do not need to strip the leather first. (Stripping leather means that you use a strong solvent such as acetone or alcohol to remove all the oil... we don't want to do that.)

Be careful to get the right thing... most of the stuff called "leather dye" in shoe repair shops is really just paint for changing the color of women's shoes. It would be like putting black paint on your boots.

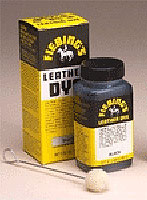

In the US, the best known manufacturer of genuine leather dye is Fiebing's... available from Tandy. Excellent dye is also made by Angelus and Lincoln. Each of these manufacturers sells several types of dye.

- Avoid: "Oil Dye", "Acrylic Dye", "Leather Stain", "Institutional Leather Dye" (for schools and nursing homes), "Water Based Dye", "Dye for Vegetable Tanned leather" and anything which is "non-flammable", "new and improved", "safe" etc... you need the one that works because it isn't safe to drink or use in a primary school. Also avoid dye which says that you must first use leather stripper to remove the oil in the leather. That means that it's a wimpy, wannabe dye.

- Look for: "Alcohol Based", "Spirit Based", "Penetrating", "Permanent", "can't be shipped by air", "ground shipment only", "ORM-D" as clues that you're getting the real article.

The Fiebing's black leather dye is often described as "USMC Black".

These dyes usually come in small 4 ounce (118 ml) bottles packed in a cardboard box with a wool swab on the end of a wire handle. If you're just dying the stitching you can use a cotton swab. The dye contains strong solvents such as ethanol and orthodichlorobenzene to help the dye penetrate through the oil in the leather and stitching.

Ethanol is the active ingredient in beer, wine and whisky. Orthodichlorobenzene is related to moth balls and has similar toxicity. Both of the solvents are very volatile and quite flammable. So use this dye in a well ventilated area away from ignition sources and avoid breathing the fumes. The dye is not poisonous and won't harm you if you get it on your skin... however your skin will stay black for a long time. Leather workers use this dye all the time with no problems (though they tend to have black fingers).

When you apply the dye, it is very thin and volatile. It runs easily since it is so thin. It easily soaks into the leather or thread then dries quickly because of the volatility of the solvents. The dye doesn't paint or seal the surface of the leather... so the leather will still breathe. As it dries, it leaves a very thin coating on the leather which has a metallic sheen with a rainbow quality like oil on water. Once the dye has dried you can wipe this sheen off with an oily rag.

- Can you make my boots with Wesco's original last which

featured the more roomy "bump" toe?

For years Wesco made their boots with their famous #9109 last which featured a toe with a slightly "chunkier" look. The toe featured a bit more vertical room in the toe area. This led people to call it a "bump toe". It was also a bit rounder (like the front of your feet) and less pointed than the current last.

A last is the form in the shape of a foot which is used to give shape to the boot as it is being built. These are made of wood and steel or, more recently, plastic and steel.

Wesco was not able to get this #9109 last for a number of years and switched to making boots using a last with a toe which with had a bit less vertical toe room and a slightly more pointed or "V" shaped toe.

Wesco is now able to get their famous #9109 last again and it is available in most sizes. Wesco has not switched back to using this original last on most of their boots but Big Black Boots specifies it for all of our stock boots and for all custom boot orders where it can be used.

9109 last standard last steel toe The fit on this last is the same as the standard last which Wesco is currently using except that it tends to feel more spacious in the forefoot because it has more vertical "wiggle room"

in the toe. Our advice on fit and sizing is this: order the same size when using this last as you

would have for the standard last.

in the toe. Our advice on fit and sizing is this: order the same size when using this last as you

would have for the standard last.

This is the last we use to build our classic stock Wesco Boss boots with the two top buckles.

Now for the fine print: This last can't be used on boots with steel toes. If you look at the vertical profile above, you can seen that the toe on this last is about the same size as a steel toe, so it doesn't leave room for a steel toe to the used on top of it. But that's OK because boots with a steel toe end up with a look and feel very similar to boots built with the #9109 last because Wesco uses special steel toes which feature more vertical room in the toe.

This #9109 last also can't be used on boots with a low heel. It is designed specifically for building logger boots which have a higher heel with the classic undercut style. The harness boots are made with a variant of the #9109 last which has a square toe shape.

- Your boots are all shown in men's sizes... what about women's sizing?

We sell lots of boots to women. Here's the story on sizing.

Our Wesco boots, Cosmas boots and the Dehner Stock Motor Patrol boots are all made using US men's sized lasts and are sized in US men's sizes.

Our Grinders boots are made using UK men's lasts and are sized in UK / British men's sizes. Like Doc Marten boots they are not made in womens sizes.

Custom made to measure Dehner boots and stock Dehner equestrian boots are be built on men's or women's lasts and are available in both men's and women's sizes.

Custom made to measure Wesco boots can be made to fit women. If you would like to have the Wesco boots custom made to your measurements, we can put you in touch with Wesco directly.

Many women wear our standard men's sized boots. To order, DO NOT TRY TO CONVERT FROM EXISTING FOOTWEAR SIZES. Footwear manufacturers are notoriously poor at standardizing sizes. Women's footwear is even more variable in sizing than men's.

Instead, go to our page on sizing your feet and follow our instructions to find your true US men's size. Use your US men's size to order your boots.

Sizing page: bigblackboots.com/bsizcvt.htm

You can measure your feet at a shoe store using the men's Brannock device instead of the woman's.

Note that women, for an equivalent size and width, tend to have slightly narrower heels than men. When you order boots built on a men's last, you may need to use a heel insert to correct the fit of the heel.

- When you describe insole and midsole construction in terms of "9 iron leather" or

"8 iron rubber" just how thick is that?

The term "iron" when used to describe insole and midsole components made of leather or rubber is used to describe the thickness of the material, not the stiffness.

1 iron is equal to 1/48". So a 6 iron midsole is 1/8" or 0.125" or 3.2mm thick

Special Treat (free!)

OK... if you read through the whole FAQ you're diligent, obsessive or just plain curious. Whatever the reason, you deserve a treat. At BIG BLACK BOOTS we're especially thrilled because you're less likely to ask dumb questions

S: (n) dumb question (a perfectly reasonable question whichwe haven't been prescient enough to have anticipated)

S: (n) dumb question (a question which has been answered in

27 different places in our web site)

e.g. "Can you make these boots in black?"

So we have an essay by John Galsworthy on quality bootmaking. It was written in 1911 and is a classic. Since it has passed into the public domain, we can include it on our website.

Please enjoy: "Quality" by John Galsworthy

BIG BLACK BOOTS Home Page

Email questions or comments to

![]()

links permitted and encouraged

Last edited 21 August, 2018 at 03:12 GMT / UTC / Zulu | 20 August, 2018 at 20:12 California / PST