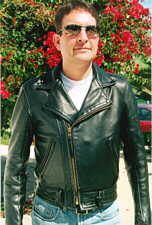

California Highway Patrol

Classic Leather Jackets

with quilted padding "CHP Colorado" |

Features:

|

The Jacket:

This is the classic leather jacket, hand crafted by Vanson using the finest leather and hardware. The design of this jacket is the classic one long used by California Highway Patrol (CHP) motorcycle patrol officers.

The jacket isn't simply a "fashion" item. It's built to be worn by motorcycle riders who expect a comfortable jacket which provides protection from the weather and the road.

Vanson jackets are constructed of the finest top-grain leather custom tanned to Vanson's specifications. The heavy but supple leather is hand waxed to bring out its unique character. The jacket's seams are double stitched with extremely heavy gauge nylon thread and only the heaviest brass hardware is used. The result is a heavy and sturdy leather jacket absolutely unlike the flimsy fashion jackets you'll find in your local shopping mall. This is the real thing.

Did we mention that these jackets are heavy and sturdy?

The CHP jackets shown on this page each weigh about 6.5 Lbs / 3 Kg

Did we mention that these jackets are heavy and sturdy?

The CHP jackets shown on this page each weigh about 6.5 Lbs / 3 Kg

Did we mention that they are built to last? The jackets used for the photos on this page are each several years old and have logged plenty of miles along the Big Sur coast of California.

In 2005 Vanson made a small improvement in the fit of these jackets in the shoulder area and changed the name from CHP to CHP2 to indicate the new model. There is no visible difference in the design.

The Leather:

Cowhide

Vanson uses drum-dyed top grain cowhide which is manufactured in the USA. Vanson leather is chrome tanned, a process developed in the last half of the 1800's to create leather that is strong, durable, can be dyed and will hold that coloring. The leather is finished and waxed by hand.

Tanning is the process of converting the cellular structure of skin into a network of collagen fibers. How short or how long, how tangled or how straight is the determining factor in the stretch and the strength of the leather, and the density and complexity of that network is affected by the blend of materials used in the tanning. The random structure of this network has great tensile strength. This, as ancient toolmakers and armorers as well as modern motorcyclists know, makes for an unparalleled protective material. So good that man has been unable to duplicate or improve it for the purposes of the modern motorcyclist.

Once tanning is complete, the next step is drum dyeing where Vanson leather is tumbled for up to six hours with a mixture of oils, dyes and hot water in 12 X 12 foot oak drums. This method impregnates the leather with color and nourishes the skins making them stronger and more supple. After drum dyeing, the skins are polished and waxed to maximize the character of each hide.

Finally, finishing is the process where the leather receives its top coat and is made ready for cutting. Before finishing Vanson selects only the best tanned hides, culling out skins that don't meet their standards. Then, once the skins arrive at their cutting tables, Vanson further eliminates any inferior skins as they start the process of building your jacket.

Some manufacturers use nude leather with a smooth buttery finish. In contrast to that, Vanson leather is somewhat stiff. It is polished and its top coat, over several underlying applications of waxes, gives it Vanson's characteristically deep finish, luster and durability over time. In the worst-case scenario, when your jacket is all that's between you and the asphalt, your Vanson jacket with its different feel and hard topcoat has been proven to perform the best!

Prices:

| CHP2 Standard Jacket: Sizes 34 - 46 | $675 |

| CHP2 Standard Jacket: Sizes 48 - 54 | $745 |

| CHQ2 Colorado Jacket with Quilted Padding: Sizes 34 - 46 | $775 |

| CHQ2 Colorado Jacket with Quilted Padding: Sizes 48 - 54 | $835 |

Vanson Classic Leather Jacket Order form: Click here

About ordering from BIG BLACK BOOTS

How do I know what size jacket to order?

BIG BLACK BOOTS Home Page

Email questions or comments to

![]()

All Rights Reserved - links permitted and encouraged

Last edited 6 March, 2017 at 21:36 GMT